Understanding Cabinet Door Handle Installation: Cabinet Door Handle Installation Template

Installing cabinet door handles might seem daunting, but with the right knowledge and tools, it’s a manageable DIY project that can significantly upgrade your kitchen or bathroom. This guide breaks down the process, covering different handle types, installation techniques, and potential challenges. Mastering this skill will not only save you money but also allow you to personalize your cabinets to your exact specifications.

Cabinet Door Handle Types and Installation Methods

Cabinet door handles come in a vast array of styles, each requiring a slightly different installation approach. Understanding these variations is crucial for a successful installation. Common types include knob handles, cup pulls, bar pulls, and D-ring pulls. Knob handles typically require a single hole, while cup pulls and bar pulls necessitate two holes for mounting screws. D-ring pulls, often used on more contemporary cabinets, may also require two holes or a single, larger hole depending on the design. Installation methods generally involve drilling pilot holes, inserting mounting hardware, and securing the handle to the cabinet door. The specific steps will vary based on the handle type and the material of the cabinet door.

Step-by-Step Guide for Standard Cabinet Door Handle Installation

This guide focuses on installing a standard two-hole bar pull handle, a common and relatively straightforward type.

| Step | Tool Required | Description | Potential Challenges |

|---|---|---|---|

| 1. Measure and Mark | Measuring tape, pencil | Carefully measure the distance between the handle’s mounting holes and mark the locations on the cabinet door. Ensure accurate placement for a symmetrical and aesthetically pleasing result. | Inaccurate measurements leading to misaligned handles. |

| 2. Drill Pilot Holes | Drill, appropriate drill bits | Drill pilot holes at the marked locations using drill bits slightly smaller than the handle’s mounting screws. This prevents the wood from splitting and ensures a clean installation. | Drilling too large a hole, resulting in loose handles. Drilling at an angle. |

| 3. Insert Mounting Hardware | Screwdriver | Insert the handle’s mounting hardware (usually screws or bolts) through the pilot holes from the inside of the cabinet door. | Stripped screw holes. Difficulty accessing the back of the cabinet door. |

| 4. Attach the Handle | Screwdriver | Attach the handle to the mounting hardware, ensuring it’s securely fastened. Tighten screws evenly to prevent warping or damage. | Over-tightening screws, potentially damaging the handle or door. |

Drilling Pilot Holes: Size and Handle Type

The size of the pilot hole is critical to prevent wood splitting and ensure a secure fit. Using the wrong size can lead to loose handles or damaged doors.

Cabinet door handle installation template – Choosing the correct drill bit size is paramount. Here’s a guide:

- For small knob handles and thin screws: 1/8 inch drill bit

- For standard two-hole handles with small screws: 5/32 inch drill bit

- For larger two-hole handles with thicker screws: 3/16 inch drill bit

- Always consult the manufacturer’s instructions for the specific drill bit size recommended for your chosen handle.

Installing Handles on Different Cabinet Door Materials

The installation process varies slightly depending on the cabinet door material.

Wood, metal, and glass doors each present unique considerations:

- Wood: Wood is generally the easiest material to work with. Pilot holes are crucial to prevent splitting. Use a slightly smaller drill bit than the screw diameter.

- Metal: Metal doors may require specialized drill bits and potentially different mounting hardware. Use a drill bit designed for metal and ensure you have the correct screws for the thickness of the metal.

- Glass: Glass doors require extra care. Use a specialized glass drill bit and work slowly to avoid cracking the glass. You may need to use specialized mounting hardware designed for glass.

Using Templates for Precise Placement

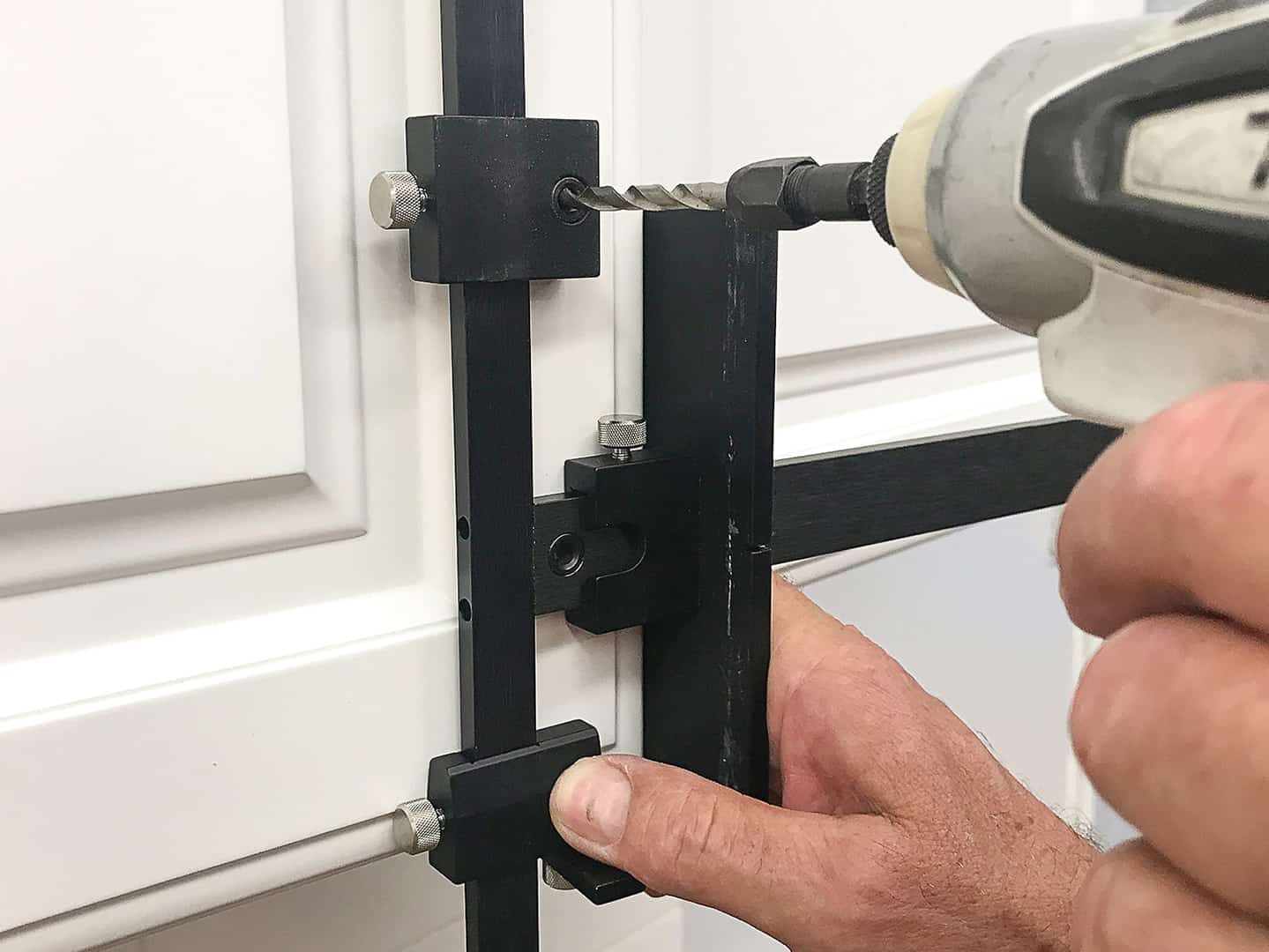

Achieving perfectly aligned cabinet hardware across multiple doors is crucial for a professional finish. A simple, yet highly effective method to ensure consistent placement is using a template. This guarantees uniformity and significantly speeds up the installation process, saving you both time and frustration.

Creating and using templates ensures that your cabinet door handles are installed with precision and consistency, leading to a polished, professional look. This is especially important when working with multiple doors of the same style, where even slight variations in handle placement can be readily noticeable. The time saved by using a template is also a significant advantage, especially on larger projects.

Template Creation from Readily Available Materials

A simple template can be constructed using readily available materials. For example, a sturdy piece of cardboard (like a cereal box), a thin piece of plywood, or even thick plastic sheeting can serve as the base. Mark the center point of the template, representing the center of the handle’s mounting holes. Then, measure the distance between the handle’s mounting holes from center to center. Using a ruler and pencil, mark these points on the template, accurately reflecting the handle’s dimensions. You can also add markings for the screw holes themselves, if needed. Once the markings are complete, carefully cut out the template to the desired size and shape, ensuring that the markings are protected and easily visible.

Advantages of Using Templates

Templates offer significant advantages in cabinet handle installation. Firstly, they guarantee consistent handle placement across all doors, resulting in a highly professional and uniform appearance. Secondly, they dramatically reduce installation time. By pre-marking the locations, you eliminate the need for repeated measurements on each door, significantly speeding up the entire process. Finally, templates minimize the risk of errors, ensuring accurate hole placement and preventing costly mistakes like misaligned handles or damaged doors.

Pre-Made versus Custom Templates

Pre-made templates offer convenience but may lack the flexibility to accommodate specific handle designs. Custom templates require some initial effort but provide perfect fit and customization.

Pre-made templates, often available at home improvement stores, offer a convenient solution for standard handle sizes. However, their limited range of sizes and designs may not always be compatible with your chosen hardware. Custom templates, on the other hand, provide the flexibility to perfectly match the dimensions of any handle. While they require a small amount of upfront work to create, the accuracy and customization they offer are invaluable for achieving a truly professional finish. The time saved in the long run often outweighs the initial effort of creating a custom template, especially for larger projects involving numerous doors.

Transferring Template Markings Accurately

To accurately transfer the template markings to the cabinet doors, place the template centrally on the door, ensuring it is aligned correctly. Use a sharp pencil or marking tool to carefully trace the markings onto the door. Employ a light touch to avoid excessive pressure that could damage the door’s finish. Double-check the placement before drilling any pilot holes. Using a level to ensure the template is perfectly horizontal and vertical is highly recommended to avoid any misalignment. After transferring the markings, remove the template and carefully drill pilot holes at the marked locations, before installing the handle. This precise approach minimizes the risk of mistakes and ensures a flawless installation.

Troubleshooting and Advanced Techniques

So, you’ve tackled the basics of cabinet handle installation, and you’re feeling pretty confident. But what happens when things don’t go exactly to plan? This section dives into the common pitfalls and offers solutions, along with some advanced techniques to make your next project even smoother. We’ll cover everything from fixing those pesky misaligned holes to tackling trickier door styles.

Common Installation Problems and Solutions, Cabinet door handle installation template

Let’s face it: even the most experienced DIYer runs into snags. Here are some common problems encountered during cabinet handle installation and their solutions. Think of this as your handy troubleshooting guide, saving you time and frustration.

- Problem: Stripped screw holes. This happens more often than you might think, especially with cheaper cabinet hardware.

Solution: Use a slightly larger screw, a wood filler to rebuild the hole, or even consider using a stronger type of screw, like a self-tapping screw designed for hardwoods. - Problem: Misaligned holes. This often results from inaccurate template placement or drilling.

Solution: Carefully use wood filler to repair the existing holes, and then redrill using a fresh template. Take your time to accurately position the template before drilling. Measure twice, drill once, as they say! - Problem: Handles don’t fit flush against the door. This is a common issue and usually stems from incorrect handle selection or inconsistent door thickness.

Solution: Double-check your measurements against the handle specifications. If the problem is with the door, you might need to use shims to create a consistent thickness. In some cases, a slightly longer screw might help.

Installing Handles on Doors with Unusual Configurations

Installing handles on standard doors is one thing; tackling inset doors or those with curves adds a whole new layer of challenge. Here’s how to handle these unique situations.

- Inset Doors: Inset doors sit flush within the cabinet frame. Accurate template placement is crucial. You’ll likely need to account for the recessed depth of the door when marking your hole positions. Use a depth gauge to ensure consistency. A countersink bit might be necessary to create a recess for the handle base to sit flush.

- Curved Doors: Curved doors require a more flexible approach. Traditional templates might not work perfectly. You might need to use a flexible template material, perhaps even creating a custom template from flexible plastic or cardboard that conforms to the curve of the door. Pre-drilling pilot holes is especially important here to prevent splitting the wood.

Advanced Techniques and Specialized Tools

Taking your cabinet handle installation to the next level involves using some specialized tools and techniques. These will ensure accuracy and efficiency, resulting in a professional finish.

Using specialized tools and jigs can significantly improve the accuracy and efficiency of your cabinet handle installation. These tools can minimize errors and save you time and effort.

- Self-Centering Drill Bit: These bits ensure that your holes are perfectly centered, regardless of the template’s alignment. They are especially helpful when working with multiple doors.

- Depth Stop Collar for Drill Bit: This prevents you from drilling too deep, ensuring consistent hole depth and preventing damage to the door.

- Adjustable Handle Jig: These jigs offer precise hole placement for different handle types and center-to-center measurements. They are particularly useful for large-scale projects or complex handle designs.

- Countersink Bit: This creates a countersunk hole, allowing the screw head to sit flush with the surface, providing a clean, professional finish.